|

|

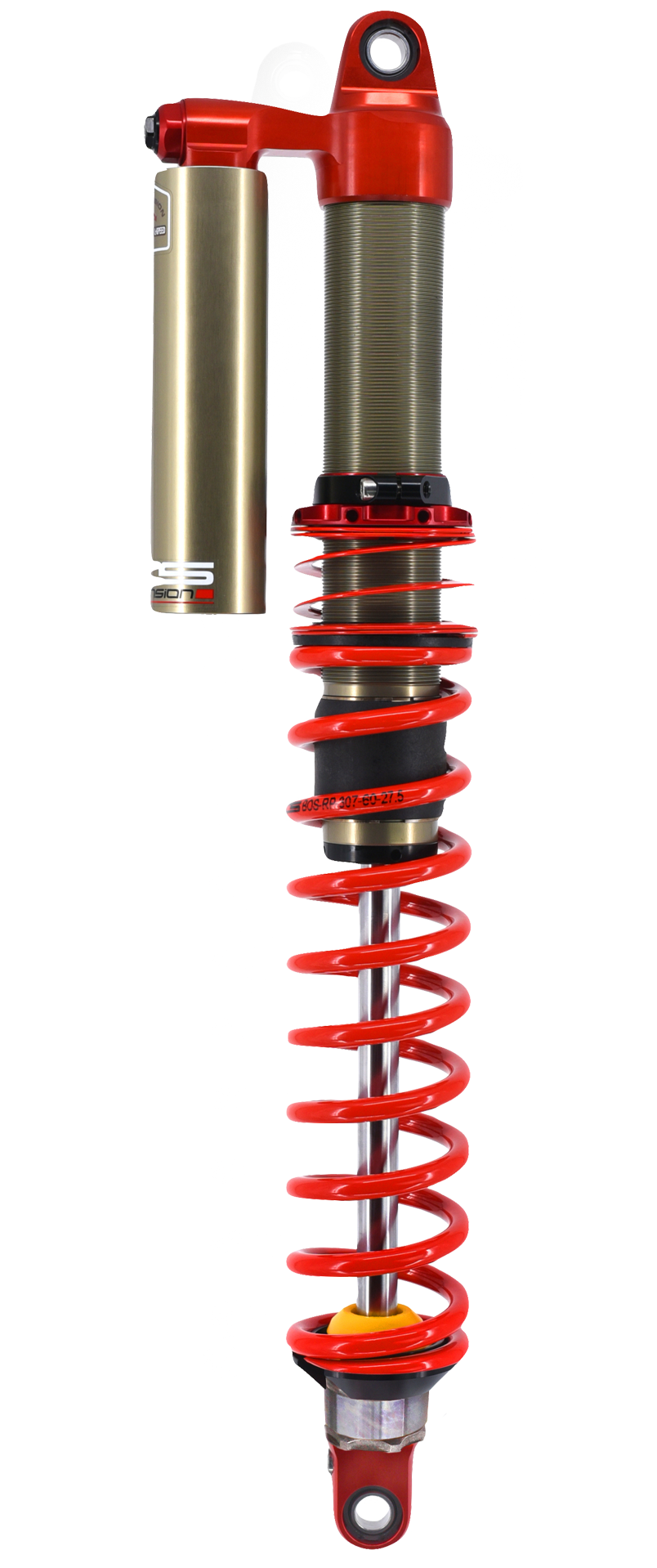

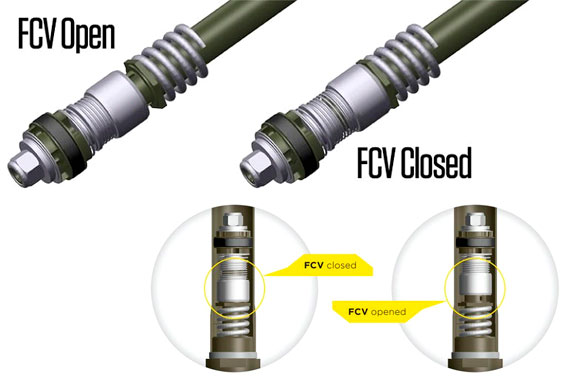

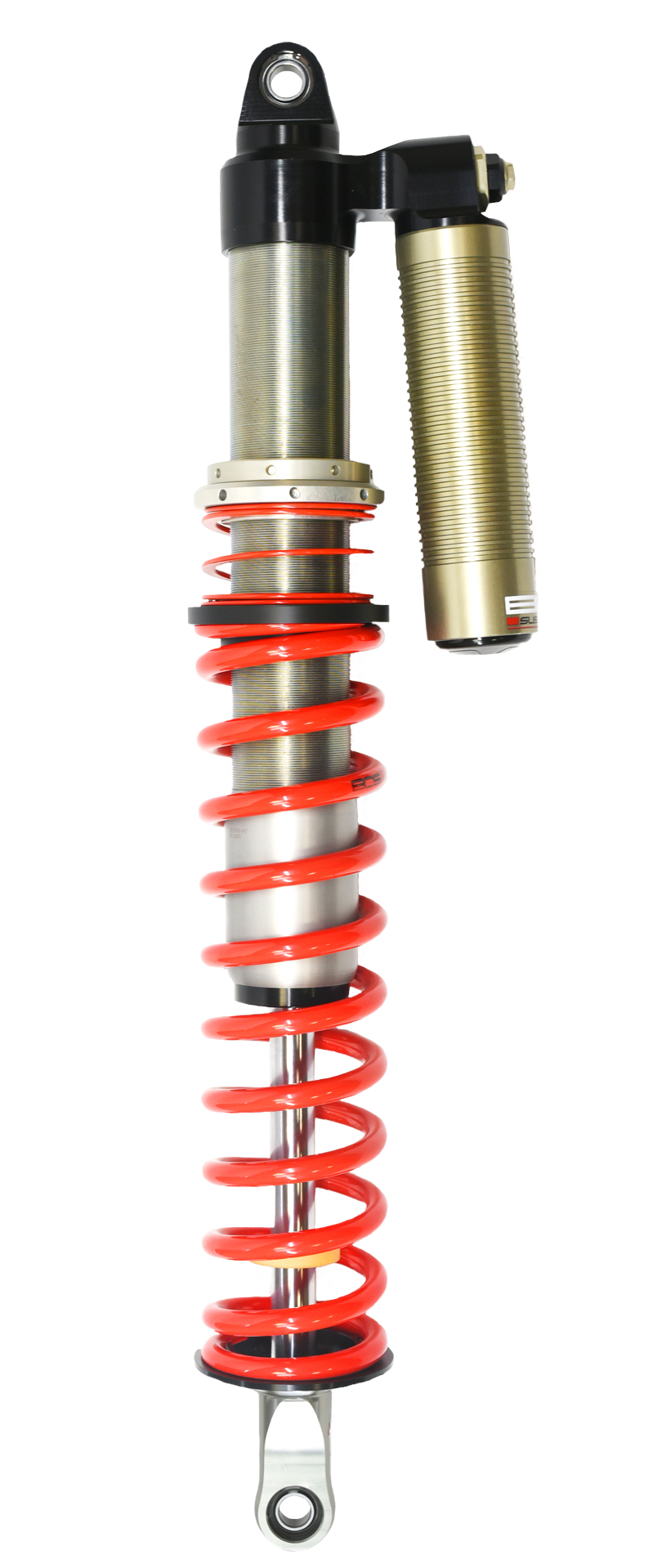

In 20 years, BOS has filed more than a dozen patents.. Because not being ahead of your time is already being behind the competition.  CAS Technology, Selective Damping Control : put all the power to the groundInitially tested on mountain bikes in 1999, it attracted attention with the victory of Nicolas Vuilloz in the world championship in 2001 and 2002, and was then adapted for the Dakar Rally, won in 2005, 2006 and 2007 on a BOS. It is a very efficient principle: it corrects the shock absorber hydraulics according to the load applied to the wheels, allowing a faster grip recovery and a better traction. We have used this system a lot, especially in cars since 2005 with Mitsubishi. When there is no more load applied, the shock absorber's resistance corrects itself to allow the wheel to follow the terrain and regain contact with the ground. It allows for better traction, acceleration and braking grip, as it maximizes contact with the ground. This technology is the result of a long work on the dosage of the loads applied to the damper. The system is closed at standstill. As soon as the applied load is lower than the system stiffness, the system opens. This is equivalent to accelerating the damper after the compression phase. As soon as the contact is recovered, the normal hydraulic curve is restored. Available for CR and XC Ranges THE ADJUSTABLE HYDRAULIC STOP : A significant plusOn the shocks, the stops prevent the shock from bottoming out at the end of the stroke. But they don't prevent the rider from feeling the shock when the shock goes into full travel. Traditional bumpstops may prevent heeling, but when it's not progressive, it makes a shock at the end of the stroke. As soon as there is a little bit of energy, the rider will feel it. The BOS engineers have done a lot of work on energy dissipation at this key moment. We worked a lot with the car manufacturers on this system. The big job was to switch the system on the bike. For us, it's a no-brainer to put a hydraulic stop; we've been using it since 2003 in Rallye-Raid and WRC The hydraulic stop is a system which allows to harden considerably the suspension at the end of the stroke, in order to avoid the heeling and to improve the management of the travel (feeling of infinite travel). Managing this function by a hydraulic system allows the response to vary according to the stress, giving it an excellent progressiveness. This also avoids the violent relaxation generated by a foam buffer or by a pneumatic system. Its behavior is precisely defined at the time of design and allows to ride with a softer hydraulic curve for more comfort in the middle of the travel.   AMX1 BOS Suspension's Oil: an almost unalterable quality, whatever the temperatures encountered. The BOS suspensions were inspired by the most difficult special stages of the Dakar, the bumpy fields, the camel grass, which stresses the suspensions for hundreds of kilometers without stopping. We have focused our development on the most demanding stages. The result is that the suspensions that come out of the BOS workshops are now able to withstand the high stresses of driving. When you drive in desert temperatures, there's no point in asking the radiator to lower the temperature: you have to adapt the equipment. One of our major leitmotivs is to have the lowest possible friction. We have developed a specific oil in terms of viscosity resistance in relation to temperature, and special anti-friction additives. We have done additional surface treatments on the parts to avoid degrading the oil. Today, our parts, i.e. the oil, the seals, our manufacturing method is such that we are able to operate a shock absorber at 250°C without any noticeable degradation of its operation. FCV Technology, The Frequency Control Valve: This is a frequency control valve. One of Bos' discoveries is the FCV valve. A unique system that is as simple as it is revolutionary, it detects the direction of the force exerted on the suspension. It's a small, movable aluminum part that changes the hydraulic circuit depending on the direction of the excitation. If the force comes from the bottom up, as on small shocks, the bike will be softer than if the force comes from the top down, as on big shocks. This weight is activated according to the frequency of the shock wave in order to obtain a soft suspension on small shocks (excitation of the fork from the ground upwards, due to the holes to be erased) and becomes firmer on big compressions (excitation of the fork from the rider towards the ground as on the reception of a jump.) Increases the comfort in the vehicle and reduces the accelerations undergone by the pilot. This allows you to increase your speed in the most difficult passages. Less risk of punctures, less stress on all mechanical parts of the chassis. It also reduces driver fatigue in the most demanding shocks. On the rally, the feedback from the drivers has been very good, with several victories, such as in the special stages of the Dakar with Carlos Sainz. Originally developed for mountain biking: in 2013 the BOS pilot won a downhill mountain bike world cup round in Andorra. It was at this moment that the decision was made to use this technology in MX. The FCV is an answer to a problem known by the pilots: the locking of the suspensions on the biggest shocks. For a short period of time, on very big shocks, the suspensions lock up. On this point all the shocks compress in the same way and this has consequences on the fatigue of the rider. Manufacturers have always been groping for solutions, the most common temptation being to soften the hydraulic curve, giving an impression of comfort on certain impacts. The engineers at BOS Suspension have taken a rather different direction, focusing directly on the particularities of these strong impacts. You can't argue with fluid mechanics, you have to adapt to it. So we worked to be able to specifically set and redefine the threshold at which the wheel is allowed to rise during these high impacts. The solution is a new frequency sensor: The weight of the FCV system is set to move only on high frequencies. The system only opens on high impacts by increasing the flow through the flaps. Originally developed for mountain biking, this technology has proven itself in competition: in 2013 the BOS rider Rém Thirion won a downhill mountain bike world cup round in Andorra with a fork featuring the FCV. It was at this moment that the decision was made to use this technology in MX. In motocross, Livia Lancelot won with the FCV air fork less than a month after its release. In car rally, the feedback from the pilots was very good, with several victories, as for example in the special stages of the Dakar with Carlos Sainz Available on : CR8 auto shock, Obsys downhill MTB fork, Idylle downhill MTB fork, Deville enduro MTB fork   THE LOW SPEED PISTON Initially tested on the mountain bike in 1999, it attracted attention with the victory of Nicolas Vuilloz in the world championship in 2001 and 2002 and was then declined for the Dakar Rally, won in 2005, 2006 and 2007 on the BOS. The low speed piston is a technology specially designed and developed by BOS Suspension, and particularly adapted to disciplines where the level of grip is high, such as asphalt rallying or the circuit. The low speed piston is a piston specifically dedicated to the control of all "very low speed" movements, lower than 250 mm/s, which are similar to all the phases of vehicle movement, whether in rolling or pitching (diving under braking, pitching under acceleration). Contrary to a traditional shock absorber, which often manages this very low speed zone simply and solely via a loss of pressure calibrated by a leak, the low speed piston, which will be mounted "in series" with the main piston, will make it possible to work "hydraulically" on this loss of pressure, by controlling it via a piston and a dedicated valve system. It is therefore possible to achieve variations in load and stiffness for these speed zones, which are often neglected and yet so important in the control of the vehicle, in the application of the load to the tires, and in the grip feedback felt by the driver. This is an undeniable plus, because it gives an almost infinite possibility of load adjustments for these low levels of shock absorber rod speed, and therefore allows for much more precise and optimized hydraulic curves. It gives us this body control for all the movements of the car, which makes all the difference. Used for the first time on the "Factory Usine" settings of the Renault Clio S1600, this patent has since made the happiness of all customers eager for high level performance in asphalt rallying in particular. This patent is available as standard in some models of our CR range, and can be offered as an option on request. |